COVID-19 Saga

Ever wonder what we are up to these days? Let me tell you the saga of COVID19 and hand sanitizer at Doundrins Distilling…

Back before the state shut down, Doundrins decided to close a couple of days early – only 2 weekends after we just started our new “Make Your Own Bloody Mary Bar”. It was a scary decision for us, but we knew it was the best for our families and patrons to keep us all safe. Right around that time, we saw that there was a lack of safety supplies-way back when all the toilet paper first started to disappear. Because of this, we thought we could help our local community members here in Cottage Grove and make a few hundred bottles of hand sanitizer. We originally posted a “pre-order” message to try to sell a small amount of hand sanitizer while we figured out federal regulation requirements and got our drug facts for labels figured out. I think our first batch was maybe 300 bottles and that was all we planned on making. It was immediately apparent from the first night we posted about the small batch of hand sanitizer that the demand was much larger. We had over 16,000 views on a single facebook post within probably 3 days of us posting it – never having shared it anywhere besides on our own business page!

Our first batch was only about 300 bottles and originally, we planned on that being it. Based on this feedback, though, we decided to make more. We spent about 2 weeks non-stop trying to source raw ingredients, bottles, lids, creating new labels, speaking with our lawyer, speaking with the TTB and FDA, and reviewing the emergency regulations published by both TTB and FDA over and over again. As I have come to say, there were 15 balls in the air and they all had to land at the same time to make it work. After a lot of hard work and sleepless nights, it ended up coming together. We decided to take the money we had saved up for our outdoor cocktail garden and risk it to help our community and hopefully in turn keep our business afloat. We bought 300-1 gallon containers, 3000-8 oz containers, and we had about 6000 glass 16 and 4 oz bottles we planned to originally use for bitters on site. We pre-sold all of those very quickly. We initially hired 5 people and got everyone trained over a period of a few weeks while we figured out how to fill all of these bottles individually by hand. We spent a couple weeks filling those bottles and those orders. Maybe 3-4 weeks after we started making hand sanitizer we finally had caught up on our pre-orders enough to start selling individual bottles for walk-up sales in our new “Tasting Room” sales hours.

Somewhere in there we connected with a customer who wanted hand sanitizer in bulk (275 gallon totes). We spent about a week or two working through that supply chain path to figure all of that out and installing new equipment. We installed a grounding system so we can unload tanker trucks, bought another forklift, bought a bunch more heavy duty pallet racking for storage, a large scale to batch totes, and installed a new large reverse osmosis (RO) system to make water. Before this whole thing our RO system was making about 300 gallons per day into 1 tote. We had to repipe our storage system and increase to 6 totes to hold all the water because our new system makes 4,000 gallons/day and we need every drop of it! We received our first tanker truck and figured out what the heck we were doing and we were in business.

Having pre-sold/sold through most of that round of bottles, we moved onto more sourcing. We ended up buying around 12,000-16 oz bottles, 8,500-8 oz bottles, and 1200 more 1 gallon containers. We continued preselling. After only a week or so we decided to order another 1200-1 gallon containers and get on a pre-order list for 50,000 more 16 oz bottles. We bought another 10,000 – 8 oz bottles and continued to keep working. We were so behind on gallon orders (they take a lot longer to fill) and they just kept coming in, so we decided to get a whole semi truck of 1 gallon containers (10,500 more). All the while we had to continue ordering boxes, taking calls, answering emails, managing a staff that has grown to 14 people working 2 shifts, 5-6 days per week, managing our walk-up store hours 3 days a week, and continuing to make hand sanitizer in bulk for our large customer. We also ripped down our fence around the outdoor cocktail garden so semis could use it for a turnaround and boy it makes us really ready to get that cocktail garden built once this is all over! We turned our tasting room into a storage space and moved all of the chairs to our garages at home to clear everything out.

I am all about the stats so here they are: We ended up ramping up to about 21,000 gallons per week of hand sanitizer so far! To date we have sold over 60,000 individual bottles and made a total of over 140,000 gallons of hand sanitizer. We have directly shipped product to Florida, Arizona, Iowa, Michigan, North Carolina, South Carolina, Colorado, New Mexico, Minnesota, Illinois, Nebraska, Nevada, New Jersey, Kansas, Virginia, and of course distributed product throughout Wisconsin. We also have other large distribution companies selling our product all over the country. We have been able to help local police officers, EMT personnel, fire fighters, the National Guard, Wisconsin DNR, truck drivers, grocery store workers, pharmacies, nurses, doctors, medical supply companies, laboratories, manufacturing companies, gyms, dentists, car dealerships, realtors, construction workers, electricians, HVAC companies, auto repair businesses, food delivery drivers, restaurants, liquor store owners, hardware stores, sporting goods stores, hair salons, individuals with their personal needs, and small business owners who are essential and still open as well as those preparing to get back open safely. That is all I can think of offhand, but I am sure we missed plenty of others because our hand sanitizer seems like it is everywhere! We are grateful for everyone’s continued support and we are extremely happy we have been able to help back in this time of need.

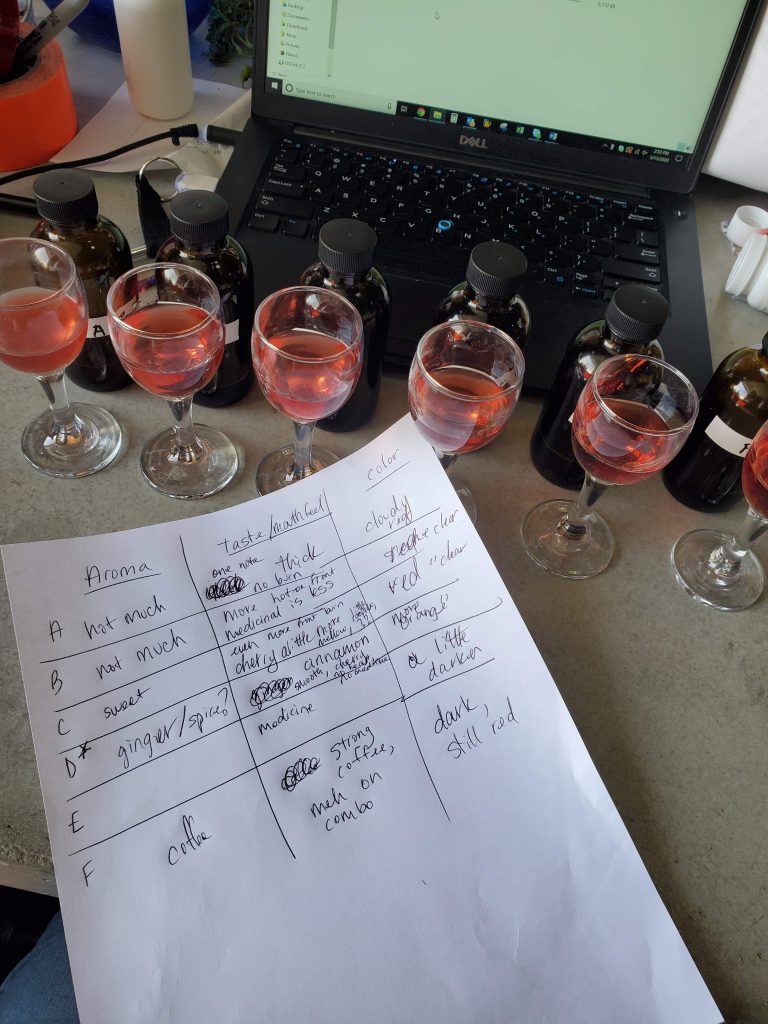

Oh, and on top of all of this, don’t forget – we still make alcohol, you know, the whole reason we actually exist as a business! In the beginning of all of this madness we got our 2020 supply of maple syrup (2000 gallons!) and made a bunch of Maple Syrup Liqueur. We also finalized a Cherry Rum recipe recently and started a new batch of rum fermenting – release coming soon! (Also- sidebar – did you know there is a sugar shortage on top of all of this nonsense because of a drought in Mexico causing sugar cane crop losses? Well you do now!) We finalized our Gin recipe – for those of you “in the know” – it’s Gin #5. Not sure on release timing of that product yet as it is going to be fairly labor intensive. We have made a couple batches of vodka and started distributing 3 more products. We expanded our placements of spirit bottles to numerous new locations and are continuing to work to do more. We did a couple large bottling runs of Green Tea Vodka and White Rum. We sold the last of our Spicy Pepper Vodka from last year and got the first of 2 gardens planted with veggies for our 2020 seasonal products. We ran a mini batch of an experimental maple product – news is in, it was just ok. We have also now started distilling a small-batch run of Whiskey for the Vintage Brewing Co. We finished aging all 3 of our 2019 harvest season Immature Brandys and got more brandy in barrels for the long 2 year wait to get regular “Brandy”. By the way – we LOVE how the Immature Brandys turned out and can’t wait to finalize the blend. We are starting our next batch of Honey Liqueur next week. By the end of this we also need to get our new soda gun installed that we bought right before the start of the shutdown and reorganize our back-bar area to make it more efficient for our bartenders.

We are still selling spirit bottles, merchandise, beer, and hand sanitizer at our walk-up sales hours 3 days a week (Wed, Thurs, and Fri from 5:30PM-8PM). Our tasting room and production spaces are both unrecognizable right now but for good reasons. We are happy to say that Doundrins Distilling Tasting Room will be back once this is all over and we feel we have both thoroughly met the needs of our community and customers for hand sanitizer as well as feel safe for ourselves, our employees, and our patrons, to allow people to come back in.

For now we are closed, but we will drink together again my friends! In the meantime, please stop by for all your alcohol and hand sanitizer needs. Feel free to tell your friends about us if they need anything, and above all – stay healthy and safe!